Additional

Description:

• 10.4” color screen

• CNC user memory 10MB

• USB, CF card, RS232 data transfer

• Acceleration with jerk limiting

• Dynamic servo control in the drives

• Advanced position control

• Tool lifetime monitoring

• Measuring system and spindle pitch compensation

• Friction compensation

• Motion synchronized actions

• Asynchronous subprograms

• SINUMERIK CNC programming language with high-level language

elements

• DXF reader

• Program guide

• Technology cycles for turning

• Shop Turn machining step programming

• CNC Simulation for turning (3D)

• Context sensitive on-board help system

• On board signal, bus and network diagnostics

• On board maintenance and service tools

• Work zone limiting

• Nodding Compensation: Nodding compensation is used to compensate

dynamic position deviations that occur when machine axes accelerate. This improves

machining quality, and at the same time, allows higher jerk and acceleration values to be

reached. Siemens 828 Control SC Series Machines:

User-Friendly Equipped with a full QWERTY CNC keyboard with short-stroke keys

and a high resolution 10.4” color display. The 828 control is extremely easy to

operate. Equipped with USB, CF card and RJ45 interfaces at the operator panel CNC data can

be quickly and easily transferred.

Precision Siemens drives compute with high-performance 80-bit NANO accuracy. This

eliminates rounding errors and results in an extremely high internal computational

accuracy in the complete controller circuit.

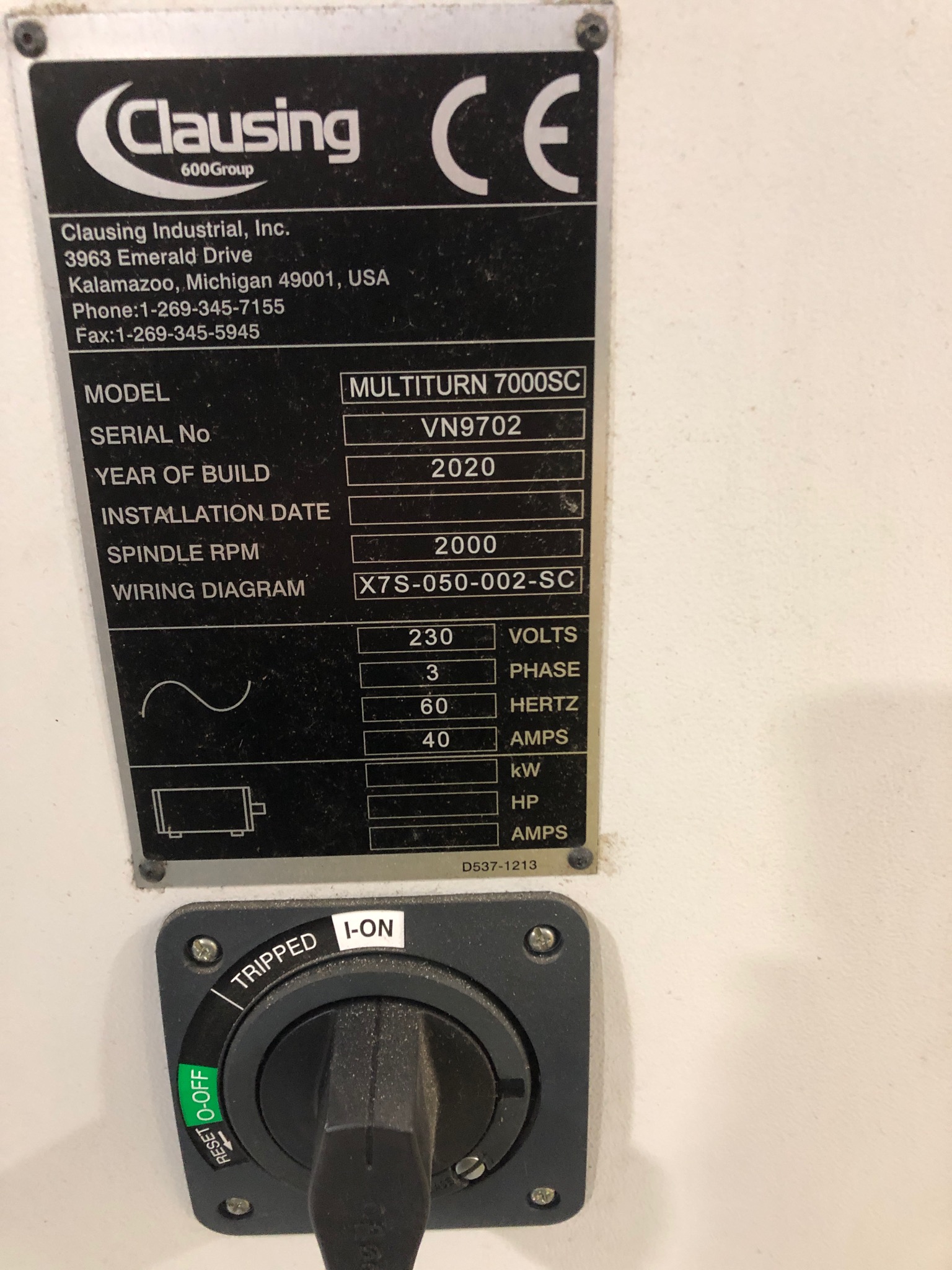

Clausing Multi-Turn CNC7000 Machine Features

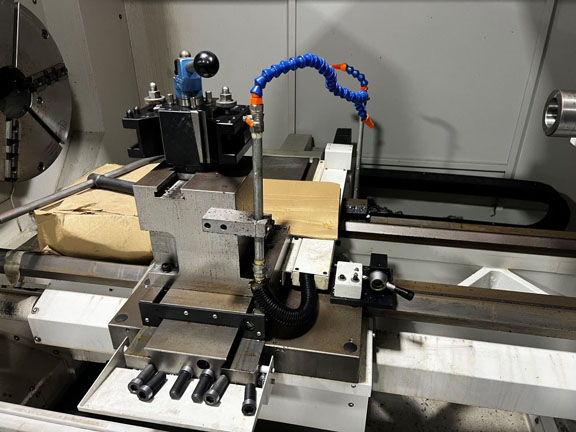

• Highly versatile flat bed design lends itself to a wide range

of applications including job shops, tool rooms, educational facilities, shaft production

and low to medium production runs.

• Headstock spindle, shafts and gears are made of high grade alloy

steel, hardened and precision ground for higher speed operation with less heat and noise

generation.

• Superior headstock lubrication with an external electric oil pump

ensures a long life of spindle bearings and gearing.

• 4.09” Spindle Bore D1-11 camlock spindle 26-2000 RPM

• Anti-friction PTFE material between saddle and bed greatly

reduces friction and has superior dampening properties to reduce chatter during machining

cycles. The low friction PTFE minimizes bed wear and extends the life of the machine.

• Heavy-duty cast iron bed ways are induction hardened over 50 Rc

to a minimum depth of 0.060 inch.

• Extra wide 18.9" bed maximizes support for the saddle and

cross slide assembly for smooth machining of even large components. Heavily ribbed

construction ensures very high torsional stiffness, eliminating bed deflection even during

heavy roughing cuts.

• Variable AC spindle drive provides 20Hp (Continuous) and 25Hp (30

Min Rated) for exceptional machining power.

• Three-range headstock allows full horsepower to be reached at 64

rpm allowing more efficient machining of large components or of harder materials such as

stainless and tool steels.

• Automatic central oil system with low oil alarm maintains proper

lubrication to slide ways and ballscrews.

• Digital AC servo drive system provides powerful and accurate axes

positioning.

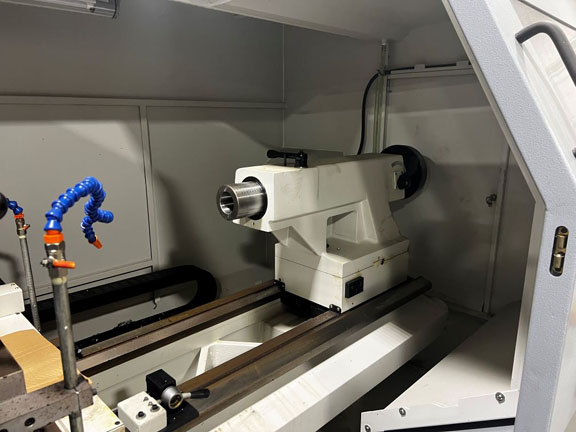

• Fully enclosed work area with 2 interlocked doors for clean and

safe work areas.

• Front roll-out chip tray provides easy and efficient chip

removal.